The My Home Sayuk project will comprise of 12 residential towers, each overlooking a central courtyard. Designed to foster a sense of connection, the project uses Vaastu, the traditional Hindu system of architecture.

An ambitious project like My Home Sayuk, comes with logistical challenges, especially when it comes to the vertical transportation of materials and personnel. In high-rise construction, every delay counts. That’s why the project team chose the AlimakTM Levato 450 construction hoist – a cost-effective, modular solution that keeps productivity on track and timelines in check.

To meet the rigorous demands of the project, two Alimak Levato 450 construction hoists were installed. Each boasted a robust payload capacity of 2,000 kg, easily handling heavy and bulky loads. With a travel speed of 60 m/min each hoist was able to provide fast and efficient vertical movement throughout the build.

With strict space constraints, the modularity of the Levato 450 meant installation was straightforward. Opting for a 1.4m wide by 3.0m cage size, both hoists were the ideal size to boost productivity throughout construction. The project had a total lifting height of 140 m; by opting for a VFC motor drive, the Levato 450 was able to travel at a speed of 60 m/min, ensuring productivity remained a priority.

The Alimak Levato 450 runs on Alimak’s proven rack and pinion technology, ensuring reliability and durability in all conditions. The robust design ensures optimum performance, despite the hot and humid Hyderabad weather. Its intelligent control – powered by Alimak’s ALC III – optimizes performance by automatically selecting the most efficient operational mode to reduce wait times and increase productivity.

With an improved car door design, the Levato 450 further enhanced on-site performance by simplifying installation and minimizing setup time. This meant faster deployment and less downtime, both key advantages in a high-pressure build environment.

When you’re building prestigious structures, you need equipment that performs. The Alimak Levato 450 construction hoists delivered increased productivity, enhanced safety, and modularity — a trusted choice for high-profile developments like My Home Sayuk.

HOIST DETAILS

Location: Hyderabad, India

Application: High-rise construction

Hoist type: Alimak Levato 450

Hoist capacity: 2,000 kg

Hoist car size: 1.4 x 3.0 x 2.13 m (W x L x H)

Speed: 60 m/min

Lifting height: 140 m

No. of landings: 40

The Huajiang Canyon Grand Bridge, set to become the world’s tallest bridge upon completion, emerges as a marvel of modern engineering in the heart of Zhenfeng County, Guizhou Province, China. Alimak was essential in this ambitious project by supplying two single-cage Alimak SC 65/32 construction hoists built on rack and pinion technology.

The selection of Alimak as the preferred provider stems from our reputation for safety and reliability. This was a result of the successful deployment of the Alimak SC 65/32 in the construction of the Guizhou Yunwu super large bridge (with a height of 310 metres), demonstrating the client’s trust in Alimak’s vertical access solutions.

The Huajiang Canyon Grand Bridge project in Guizhou faces distinctive challenges due to its location atop the Castel geomorphology and geology canyon. Guizhou occupies the pinnacle of this geological formation, positioned in the alternating zone between the Yunnan Plateau and the Lower Yangtze Valley Plain, resulting in frequent shifts between cold and hot air.

Furthermore, being in a plateau region intensifies atmospheric temperature differences between day and night, leading to the likelihood of severe convective weather and consistent valley winds throughout the year.

In the initial stages of project investment, Alimak, aware of these hydrological environments, collaborated closely with the customer. Alimak provided comprehensive wind calculation reports and installed a solar energy-powered anemometer that connects wirelessly with the Alimak control system ALC and professionally addresses these specific challenges. This strategic integration of an anemometer is pivotal in ensuring operational safety.

The project demanded expertise and a robust design, particularly for higher wind speeds and an extended mast tie requirement. This specialised tie was crucial due to specific considerations. The decision for an extra-long mast tie arose from the bridge structure’s upward contraction in both directions, eliminating the possibility of inclined installation.

The hoist has been positioned vertically at a 90-degree angle to accommodate the upward contraction of the bridge structure in both directions. To address this requirement, mast ties longer than the maximum standard Alimak ties (4.2 m) were necessary. Consequently, the Alimak ties were extended using tie extensions provided by the customer by our force calculations.

Furthermore, Alimak deployed the Alimak SC 65/32 design to overcome these challenges, underscoring the company’s commitment to precisely navigating unique project requirements.

The primary objectives of the vertical access solution provided by Alimak were twofold: Firstly, it facilitated the seamless transportation of construction personnel and essential tools to the bridge deck, ensuring the workforce’s safe and efficient mobility. Secondly, it was strategically deployed to navigate the challenging terrain, allowing the construction hoist to ascend to the climbing formwork level.

The bridge’s main structure is expected to be completed by the end of 2024, with the bridge set to open in early 2025. The bridge’s longest span stretches 1,420 metres, and its clearance below 625 metres will make it the world’s highest bridge.

HOIST DETAILS

Location: Huajiang Grand Canyon Bridge, Zhenfeng County, Guizhou Province, China

Application: Bridge

Hoist model: Alimak SC 65/32 FC

No. of units provided: 2 (single)

Capacity: 2,000 kg

Hoist car size: (W x L x H) 1.5 m x 3.2 m x 2.5 m

Speed: 0-60 m/min

No. of landings: 2

Lifting height: 190.5 m

The Oyu Tolgoi mine is a combined open pit and underground mining project located in the south Gobi Desert in Mongolia.

Renowned as the most significant financial undertaking in the history of Mongolia, the mine is expected to produce over 450,000 tonnes of copper every year. The mine shipped its first batch of copper in July 2013.

Alimak recently installed an SC 45/30 industrial elevator on a course ore storage building at the mine. The elevator boasts a 2,000kg capacity and a lifting height of 41m. The elevator car size measures 1.4 x 3.0 x 2.13m and with travel speeds of up to 36m per minute.

The Alimak elevator was first proposed to the mine for its reliability, durability, and enhanced safety features. Most importantly, the robust elevator met the project’s needs to operate efficiently in the cold and dusty conditions that Mongolia is known for in the winter.

The most challenging aspect of this installation was to align the elevator installation and operation with the client’s stringent safety and quality requirements, which are inherent in a project of this nature. Alimak offered project management and training throughout the project to ensure that safety standards were maintained at all project stages.

To provide safe and reliable access to the coarse ore storage building, the project required further upgrades and reinforcement to ensure the crew had safe access permanently.

Alimak is proud to have played a role in delivering the elevator solution for the coarse ore storage building at the Oyu Tolgoi mine, a project that marks a significant milestone in Mongolia’s history.

ELEVATOR DETAILS

Location: Khan Bogd, South Gobi, Mongolia

Industry type: Mining

Application: Coarse ore storage building

Elevator model: Alimak SC 45/30

Elevator capacity: 2,000 kg

Elevator car size (W x L x H): 1.4 x 3.0 x 2.13 m

Speed: 36 m/min

Lifting height: 41 m

No. of landings: 2

Six Alimak industrial elevators provide emergency escape in the tunnels of Linkou, Hukou and Taoyuan which is part of the Taiwan high speed rail project.

The Taiwan High Speed Rail (THSR) is a high-speed rail network that runs along the west coast of Taiwan. It is 335.5 kilometers long, and runs between Taipei, the capital city in the north, and Kaohsiung, the second largest city in the south. THSR began operation in the beginning of 2007. An express train capable of running at up to 300 km/h travels from Taipei City to Kaohsiung City, a distance of 345 km, in about 90 minutes.

Alimak was asked to provide a solution for emergency escape in the tunnels and suggested their rack and pinion elevator with some special features added to it to suit the application. All elevator cables are flame retardent to eliminate the risk of gases created by burning

cables in case of a fire.

Two Alimak elevators are installed at the second longest tunnel among tunnels of THSR project, the 6.4 km long Linkou tunnel. The elevators has 3,000 kg payload capacity and lifting heights of 36.5 m. One Alimak elevator with 2,400 kg payload capacity and a lifting height of 8.63 m is installed inside the 4.3 m long Hukou Tunnel located about 70 km from Taipei. Three Alimak elevators with 2,400 kg payload capacity and lifting heights varying between 6.66 m and 15.93 m are installed at the three Taoyuan tunnels totalling 2.4 km. All six Alimak elevators are providing emergency escape in the tunnels. In case of fire, people can be transported with the elevators to the tunnels emergency exits at ground level. Tanamark Industries Ltd purchased the Alimak elevators for the THSR project from Alimak’s distributor in Taiwan.

ALIMAK IN THE TUNNELLING INDUSTRY

The first Alimak tunnel elevator was installed in Austria in 1975 to inspect the 600-meter deep ventilation shafts in the tunnel under the Tauern pass. Since then, Alimak elevators have been installed in a number of road and railway tunnels all over the world. They are used for transportation of personnel and materials, for inspection, maintenance, and emergency escape.

ELEVATOR DETAILS

Project: Taiwan high speed rail

Location: Taipei–Kaohsiung, Taiwan

Application: Tunnel escape shafts

Product category: Industrial Elevators

Elevator model: Alimak SE

No. of elevators 6

Capacity: 2,400 kg and 3,000 kg

Speed: 0.6 m/s and 1.0 m/s

Lifting height: Varies between 6.5 m to 36.5 m

8 Alimak elevators improve crane access at a terminal in Port of Pusan contributing to increased port efficiency. Improving access to ship-to-shore cranes for operators and maintenance personnel, the elevators provide fast and reliable vertical transport daily in any weather conditions.

The Port of Pusan is Korea’s busiest port, with about 50 thousand vessels calling annually. Also one of the world’s largest container ports, it is continually expanding its containerized cargo handling capacity. The port’s expansion includes the construction of a new terminal featuring giant shore-based container handling gantry cranes manufactured by Shanghai Zhenhua Port Machinery (ZPMC), China. ZPMC has purchased 18 Alimak elevators to provide reliable, convenient access to the cranes’ operator’s cabins. By saving time and effort, the elevators allow operators and service personnel to perform their duties much more efficiently and safely.

Alimak engineers pioneered the use of rack and pinion drive systems for the movement of men and materials, and today, Alimak is the world’s leading manufacturer of rack and pinion vertical access equipment, including a modular range of permanent access elevators as well as traditional construction hoists. The systems are easy to install and, unlike traditional rope operated equipment, require no winding room or supporting elevator shaft.

ELEVATOR DETAILS

Location: Port of Pusan, South Korea

Application: Ship-to-shore gantry cranes

Elevator type: Alimak SE 450 FC

No. of elevators: 18

Capacity: 450 kg

Elevator car size: 0.91 m x 1.3 m x 2.17 m (W x L x H)

Speed: 0.8 m/s

Lifting height: Approx. 46 m (45.658 m)

Crane manufacturer: ZMPC, China

The elevators at the Grasberg mine, Indonesia beats several records. They are both the highest situated and the deepest Alimak elevators ever installed. The Grasberg mine is the world’s largest gold mine and the highest situated mine in the world.

The Freeport-owned Grasberg mine in Papua province, Indonesia, is the world’s largest gold mine, the third largest copper mine and the highest mine in the world. The workings include a very large open pit mine, an underground mine and four concentrators. The open pit mine – which forms a mile-wide crater at the surface – is a high-volume, low-cost operation, producing more than 67 million tons of ore. When they needed to install an inspection shaft down to a level of 640 meters below the surface, the best solution they could find was the Alimak rack and pinion elevator. Installed in 1997, the elevators has operated faultless despite the extreme conditions.

The two Alimak U-600 elevators give access for service and maintenance and emergency access in a vertical inspection raise at a lifting height of 640 m each. These two elevators are both the highest situated – at an altitude of about 4,200 m above sea level – and the deepest with 640 m lifting height.

Two additional Alimak U-600 elevators was installed to give the operators access to the two crusher stations with 27 m lifting height. Besides the four Alimak elevators, five Champion US elevators have been installed at the mine operations mobile crushers, in shafts and towers.

EXPERIENCED SUPPLIER

Alimak Hek has considerable experience with installations within the mining industry both underground and surface mining applications. Alimak elevators can be found on pelletising plants, smelters, concentrators, and other ore processing plants, worldwide.

Ideally suited for operation in even the most extreme environments, the durable nature of the Alimak elevators has made it the perfect access solution for the most demanding conditions. From the freezing and exposed conditions of the Antarctic and Iceland, to the extreme heat of the Australian desert, Alimak elevators are built to last in world’s toughest environments.

ELEVATOR DETAILS

Location: Grasberg Mine, Irian Jaya, Indonesia

Altitude: ~4,200 m

Applications: Mine shaft and crushers

Elevator type: Rack and pinion

Elevator model: Alimak U-600, US 900, 1400 & 2200

No. of elevators: 9

Capacity: Varies between 600 kg and 2,200 kg

Lifting height: Varies between 27 m to 640 m

Two Alimak rack & pinion elevators were installed on new ship unloader cranes at the port of Kaohsiung in Taiwan.

The grab-type ship unloader gantry cranes will serve China Steel Corporation with bulk materials delivered from vessels. These type of cranes are often applied in bulk material discharging with high efficiency and wide usability.

The Alimak rack and pinion elevator gets the crane driver to the crane’s driver cabin at a hight of 35 metres in less than a minute, improving the efficiency and productivity further. Safety is also improved as hazards, such as slipping on the stairs or objects falling from height, are greatly reduced.

The Alimak elevators provide reliable and efficient access to three different levels of the cranes for men, tools and repair parts facilitating frequent preventive maintenance and minimizing costly downtime resulting from breakdowns. By allowing operators to access the crane’s cabin more quickly, an elevator also substantially increases the crane’s overall productivity per shift.

ELEVATOR DETAILS

Location: Port of Kaohsiung, Taiwan

Application: Grab ship unloader

Elevator type: Rack and pinion

Elevator model: ALIMAK SE 400 DOL

No. of elevators: 2

Elevator car size: 0.78 x 1.04 x 2.17 m (W x L x H)

Capacity: 400 kg

Speed: 0.76 m/s

Lifting height: 35 m

No. of landings: 4

GALLERY

Alimak industrial elevators are utilised in chemical facilities worldwide for everyday maintenance and the transportation of workers and equipment during closure times. Typical chemical plant applications for industrial elevators include boilers, chimneys, crackers, LNG & LPG tanks and towers.

The Shaanxi Yanchang Zhongmei Yulin Energy and Chemical Co., Ltd. polypropylene plant is located in the Yulin city in China’s Shaanxi province, which is known for modern oil and gas developments. Alimak recently delivered two vertical access solutions for both the desulphurisation tower and chimney located at the chemical plant after the previous successful supply of an industrial elevator for a separate flue. As such, the customer was aware of the high quality and operational stability of Alimak’s industrial elevators.

The pair of rack and pinion industrial elevators reached 79 metres and 40 metres respectively, each able to achieve a speed of 0.5 metres per second with a 450 kg capacity.

The challenges in providing this vertical access solution included the requirement for a sizeable 6-metre landing platform at the top of the first industrial elevator, which reached a 79-metre lifting height. As a result, the expert engineering team detailed the design and calculation for the extension landing platform to ensure optimal safety and reliability.

Similarly, installing the elevator mast tie on the desulphurisation tower required significant planning to overcome the challenge of an inability to impact the anti-corrosion layer that protects the tower from damage. As such, the tie brackets were fixed to the outside of the tower in advance during a period of site maintenance to minimise downtime. What’s more, the installations team successfully navigated the problematic positioning and welding requirements within this short period.

With each industrial elevator fitted with four and three landings respectively, the vertical access system will be critical to the plant’s continuous safe operation, enabling reliable access to the whole desulphurisation tower and chimney for regular monitoring.

ELEVATOR DETAILS

Industry: Chemical

Application type: Desulfurization tower & chimney

Elevator type: Industrial Elevator

Elevator model: ALIMAK SL 500

No. of elevators: 3

Capacity: 450 kg & 490 kg

Dimensions W x L x H): 1.04 m x 1.17 m x 2.2 m

Speed: 0.5 m/s

Lifting height: 79 m, 55 m & 40 m

No. of landings: 4 & 3

Alimak offshore and marine elevators are built for maximum performance and safety in the harshest maritime environments, including on offshore drilling platforms utilised in the oil and gas industries.

In these applications, continuous inspections and maintenance activities are required due to the corrosive effects of humidity and sea water, where practical access to equipment is essential. What’s more, Alimak’s offshore elevators are built to endure severe winds, as well as the roll and pitch of the ocean, to efficiently carry people and materials to elevated positions aboard a ship or platform at sea.

Alimak delivered two of the first pioneering offshore elevators in 1974, to the Aker H-3 design semi-submersible built by Aker at Stord Shipyard in Norway. The platform is currently named Nanhai II, owned and operated by China Oilfield Services Limited (COSL) and located in the South China Sea. The elevators, which have been in operation for almost 50 years, have safely transported passengers with such longevity thanks to a robust and durable construction alongside Alimak Service’s provision of an expert maintenance schedule explicitly tailored to the site’s needs.

With a lifting height of 33 metres inside two of the drilling platform’s hull columns, the Alimak OS-2 offshore elevators can handle weights of 500 kg or two passengers while lifting at speeds of 0.36 metres per second, significantly increasing efficiency and safety on-site.

Moreover, Alimak offshore elevators are built with industry standards in mind, with added safety features such as explosion and waterproofing alongside a durable construction from hot-dipped galvanised and stainless steels. This range of features makes the elevators ideal for all drill ships, semi-submersible rigs, jack-up rigs, FPSOs, TLPs, gravity-based structures, swamp barges and other offshore vessels and fixed platforms.

ELEVATOR DETAILS

Industry: Oil & Gas Offshore

Application type: Hull columns

Elevator type: Offshore Elevator

Elevator model: ALIMAK OS-2 Special

No. of elevators: 2

Capacity: 500 kg or 2 passengers

Lifting height: 33 m

Speed: .36 m/s

Manufacture year: 1974

Alimak is the pioneer and a global leader in supplying industrial rack and pinion elevators for more than 60 years. Industrial elevators provide rapid and reliable vertical access for the maintenance and repair of plant equipment in even the most challenging conditions.

The China National Building Material Group’s (CNBM) Lechang Cement Plant, located in the city of Shaoguan in South China, produces more than 100,000 tons of cement and swelling agent per year. Recently, the 30-year-old plant called on the expertise of Alimak to enhance operations and increase overall efficiency onsite.

Alimak delivered an SL-H 2000 industrial elevator to assist in production line operations for the plant. For this project, the unit, which features a 2,000 kg capacity, was required to reach a 77-meter lifting height on the plants preheater at a rate of 0.9 meters per second.

The Alimak SL-H 2000 industrial elevator proved an ideal choice for this project due to its hard-wearing nature. With the cement plant providing a challenging operating environment of high temperatures and dusty conditions, the elevators aluminum and hot-dipped galvanized steel construction safeguards against unnecessary downtime and costs due to operational breakdowns.

Similarly, the SL-H 2000’s ability to operate without a separate machine room and shaft was vital as it minimized space and building requirements. The location of the robust, high-efficiency drive system on the top of the elevator car made it the best option to retrofit on the existing site with little impact on everyday operations.

Alimak’s expert team of technicians completed the installation of the elevator. During this process, a challenge was presented when structural differences relating to the preheater tower where the elevator was being installed, were found on-site compared to what existed on provided site drawings. As a result, the design engineers were required to pivot and create a reworked solution that considered the differences in structure, which saw the car size decrease from a 3-meter to 2.4-meter length.

Alimak’s extensive range of vertical access solutions such as construction hoists and industrial elevators are tried and trusted the world over in a broad range of demanding settings. This commitment to excellence in quality and functionality for each individual project is also true of Alimak’s range of warehouse elevators which are designed to service the particular needs of this industry.

The Mah Pte Ltd, showroom and warehouse in Singapore carries world-leading motor brands including Triumph, Aprilia, Vespa and Indian. Vertical transport solutions for these large and heavy machines are a vital part of operations with a safe, efficient and reliable system being required to move the bikes between the ground floor, the showroom, the third level workshop and the fourth level warehouse.

Mah had previously been utilising an aging elevator for this purpose but the expert Alimak team were able to deliver a more appropriate solution for their needs. The new Alimak SC-IND 45 FC warehouse elevator is capable of lifting up to 1,000kg at speeds of up to 36m/s while the famously rugged rack and pinion design means there was no requirement for an elevator shaft. This presented a practical and cost-effective solution which could be easily retrofitted within the tight space available for the existing building layout.

The Alimak elevator has proven to be an indispensable investment in the smooth and efficient day to day operations and Mah has therefore wisely chosen to engage Alimak in an ongoing maintenance agreement to ensure this key investment is optimised long into the future.

The full range of Alimak SC industrial elevators are ideal for the transportation of passengers and materials. The elevators offer efficiency, safety and low cost of ownership to deliver on vertical access requirements in various industrial environments. The SC range is fitted with Alimak’s ALC lift control system with internal fault diagnostics. Standard capacities range from 2,000 kg to 3,200 kg with an explosion-proof model also available with a 1,500 kg capacity.

ELEVATOR DETAILS

Location: Mah Pte Ltd, Singapore

Application type: Motorbike workshop and warehouse

Elevator type: Rack and pinion

Elevator model: limak SC-IND 45 FC

Capacity: 1,000 kg

Elevator car size: 1.4 x 3.0 m (W x L)

Speed: 36 m/min.

No. of landings: 4

Lifting height: 13 m

GALLERY

According to Global Cement Magazine, Tangshan Jidong Cement Co., Ltd. has been ranked as the world’s sixth-largest cement manufacturer.

The busy cement production facility at Tongchuan will benefit significantly from a ready-to-use industrial elevator based on Alimak’s tried and tested rack and pinion drive technology.

As in many varied industrial applications, the vertical access solution for the plant’s important preheater tower was required to meet several specific transport requirements for the demanding industrial application. The solution delivered was made possible through Alimak’s innovative rack and pinion drive system located above the elevator car itself. As a result, there was no need for a shaft or a separate machine room, a critical feature due to the limited space available. The reliable and robust design engineered by Alimak is also uniquely well-suited to harsh industrial environments, such as cement production while also offering ease of maintenance and lower operating costs throughout its life.

A dual car, Alimak SL-H industrial elevator with a weight capacity of 2,000kg for each car maximizes the transportation capacity available for the preheater tower, reaching a height of 137 meters. The dual car design also represents significant cost savings compared to two traction elevator units.

In this instance, a pre-configured, ‘ready to use’ industrial elevator system provided by Alimak was the optimal solution, as significant challenges regarding the timescale and the limited area for installation were at the forefront of the project. In addition, the installation was also required to take place during the rainy season, adding further challenges.

A tight schedule was met to avoid undue disruption to the operations of the cement plant. With the tower crane only available for a short period, the elevator was used to complete the build of the elevator mast tower, tie-ins, and each of the ten landing areas.

As a result, three expert technicians completed the installation at a safe yet efficient pace in 35 days.

ELEVATOR DETAILS

Location: Tongchuan, Shanxi, China

Application type: Cement preheater tower

Elevator model: Alimak SL-H 2000 dual

No. of elevators: 1 dual provided

Payload capacity: 2,000 kg / car

Elevator car size: 1.4 m x 3.0 m x 2.13 m (W x L x H)

Speed: 0.9 m/s

Lifting height: 137 m

No. of landings: 10

GALLERY

Shanxi Changqing Energy Chemical Co., Ltd. Located in the Shanxi Province of China is a busy coal and chemical plant employing over 500 people in the city of Baoji. The nature of this kind of material and chemical processing activity makes the monitoring of emissions a vital part of daily operations and a suitable high quality external vertical access solution was therefore required for the chimney. Alimak was the natural choice to deliver a robust and hard-wearing outdoor industrial elevator based on a strong global reputation as the originator of the tough rack and pinion elevator drive system and an extensive portfolio of successfully deployed elevators for chimneys.

This particular project presented the additional challenge of an inclined surface with the chimney tapering inwards at an angle of two degrees. In order to achieve the best possible outcome, this necessitated Alimak’s expert team working closely with stakeholders at the plant to develop a complete turnkey vertical access solution ready for immediate use. Accurate force calculations and careful planning were required for the mast section, including foundation and installation, to ensure the SL650 FC elevator would remain level throughout its 65-metre journey. The comprehensive scope of the project also included landing platform modifications and operator training. The modifications to the platform built by the facility were required to ensure appropriate tolerance for the inclined installation.

This vertical access system will be indispensable in contributing to the continued safe operation of the plant, with four landings allowing facilitating reliable access for gathering measurements as part of the all important continuous emissions monitoring system

procedures. The elevator itself also features a wireless CCTV system located inside the car which provides a live feed to a remote monitoring centre, contributing further to effective safe working practices.

The bespoke solution this project demanded represent a number of firsts for the Alimak team including the first installation of an SL model industrial elevator on a two-degree incline and the first SL elevator to be deployed at a coal and chemical plant.

ELEVATOR DETAILS

Location: Baoji City, Shanxi Province, China

Applications: Outdoor chimney

Elevator type: Rack and pinion

Elevator model: SL650 FC levelling

Capacity: 650 kg

Elevator car size: 1040 x 1170 x 2170 mm (WxLxH)

Speed: 0.4 m/s

Lifting height: 65m

No. of landings: 4

Installation year: 2019

GALLERY

Accessing bridge pylons for service and maintenance presents one of the trickiest challenges for lift and access companies. Alimak rack and pinion lifts adapt to inclinations and curves, tight spaces and windy conditions and climb to the very top of the highest structures.

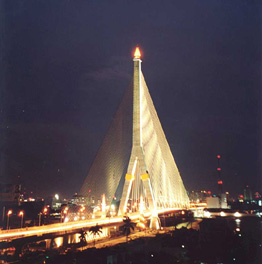

In 2002, a specially-built Alimak SE 500 passenger lift was commissioned to provide access to one of the best panoramic views of Thailand’s capital. The lift is installed inside the inverted-Y concrete pylon of the prestigious Rama VIII cabled-stay bridge, which crosses the Chao Phraya River in Bangkok. Measuring 0.9 m x 1.3 m, it travels up one of the pylon’s legs at a rate of 1 m/sec. At around 75 m, the lift slows to 0.2 m/sec to adjust for the vertical climb, and then resumes full speed for the remainder of the journey to the observation platform at the top of the 161 m-high pylon. The lift’s U-600 guide rail is curved with an inclination of 13° in the lower section and vertical on the upper section. Alimak achieved this by dividing the main frame into five pieces.

The Rama VIII Bridge is named after Thailand’s former King Rama VIII, and was officially opened in September 2002, the same year that Bangkok celebrated its 220 anniversary. It features a 300 m main span, and has two lanes in each direction for traffic, plus a bicycle and walkway lane.

Other bridge projects Other examples of bridge projects around the world where Alimak industrial lifts or construction hoists have been installed include:

- Viaduc de Millau, France

- Chung Sin, Taiwan

- Pont de Normandie, France

- Sunshine Skyway Bridge, USA

- Second Severn Crossing Bridge, UK

- Honshu Shikoku Bridges, Japan

- Tsing Ma/Ting Kau/Kap Shui Mun Bridges, Hong Kong

- Great Belt Bridge, Denmark

- Øresund Bridge, Sweden-Denmark

- Megyeri Bridge, Budapest, Hungary

ELEVATOR DETAILS

Location: Rama VIII Bridge, Bangkok, Thailand

Installation year: 2002

Application: Bridge pylon

Elevator type: Rack and Pinion

Elevator model: Alimak SE 500 SP

Capacity: 500 kg

Elevator car size: 0.91 m x 1.3 m (W x L)

Speed: 1.0/0.2 m/s

Lifting height: 151.4 m

No. of landings: 2

GALLERY

Two Alimak SC 45/30 construction hoists were utilized in the pier construction of Wenzhou Oujiang North Bridge crossing the Oujiang river in Wenzhou City, Zhejiang province, China. The Alimak hoists provided efficient vertical access for both people and materials.

Two Alimak SC 45/30 passenger and material hoists were used during the construction of the bridge pylons at Wenzhou City, Zhejiang, China. With a payload capacity of 2,000 kg and a lifting height of 150 meters, and with 1.5 degree inclination with the pylones, the hoists provided efficient vertical access during the concrete slipform construction of the bridge pylones.

The bridge is a double-deck suspension bridge with three concrete pylons and with the main spans of 2 X 800 m. Both the upper and lower decks of the bridge are designed to carry 6-lane highways.

Alimak construction hoists have been used for over 50 years in all types of applications around the world. The standard range of Alimak construction hoists offer the optimum transport solution during slipform construction of towers, bridges, buildings and dams. It performs well with inclinations and curves and follows the constantly changing structures during construction.

HOIST DETAILS

Location: Oujiang Bridge Wenzhou City, Zhejiang, China

Application: Bridge construction

Hoist type: ALIMAK SC 45/30 DOL

No. of hoist cars: 2

Capacity/hoist: 2,000 kg

Hoist car size: 1.5 m 3.0 m 2.14 m (W x L x H)

Speed: 36 m/min

Lifting height: 150 m

BRIDGE DETAILS

Carries: Dual 6-lane highway

Crosses: Oujiang river

Design: Double-deck suspension bridge

Longest span: 2 x 800 m