The construction and day to day operation of bridges and tunnels requires reliable and adaptable vertical access solutions to operate in challenging environments. Alimak has over 70 years of experience supporting the construction and maintenance of many of the world’s largest bridges and tunnels.

Whether reaching soaring heights to access aircraft warning lights or transporting heavy equipment underground, Alimak’s versatile range of permanently installed industrial elevators deliver the ideal solution for every unique bridge and tunnel application. Alimak’s elevators are adaptable to operate with inclinations and curves, tight spaces and harsh environments, including exposure to weather conditions.

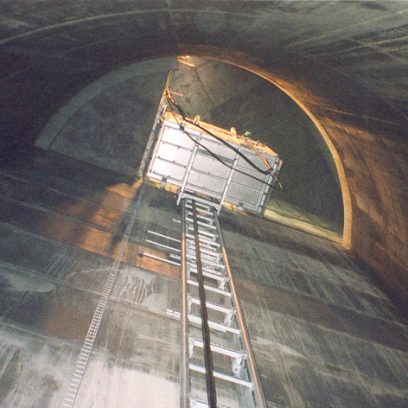

Alimak construction hoists, transport platforms and mast climbing work platforms are being used temporarily during the construction of bridges and tunnels to increase productivity and safety. Alimak hoists can be installed on slipform and jump form applications as well.

One of the key benefits of Alimak’s rack and pinion technology is that the elevators and hoists aren’t required to use a shaft or access to a machine room, making them ideal for use in small spaces such as inside bridge pylons and tunnel ventilation shafts.

The robust and reliable SE range of Alimak industrial elevators is ideal for permanent access for maintenance, inspections and emergency access in bridge, road, rail and metro tunnel applications.

An example solution provided for a tunnel application were nine Alimak industrial elevators utilised at the Copenhagen Metro tunnel to provide emergency access capable of operating in vertical escape and ventilation shafts, which are only 8-metres in diameter and need to travel up to 30-meters deep. Alimak’s SE industrial elevators were installed with a 1,200kg capacity and the elevator cars are equipped to transport two stretchers for a reliable and safe evacuation in an emergency.

The Rama VIII cabled-stay Bridge, located across Chao Phraya River in Bangkok, is another impressive example of where Alimak’s experience was called upon. Alimak was commissioned to install an elevator to travel inside the inverted-Y concrete pylon and reach the 161-metre high observation platform. A specially built Alimak SE 500 industrial elevator, measuring 0.9m x 1.3m, travels up the pylon at a rate of 1m/second, slowing to 0.2m/second approximately halfway up to adjust for the vertical climb, then resumes to full speed for the remainder of the journey.

Contact us to learn more about Alimak’s experience in the bridge and tunnelling industry.