Chemical

Alimak industrial elevators are used in chemical plants around the world for general maintenance on a daily basis and to accommodate the transportation of additional personnel and equipment during shutdown periods. Alimak’s industrial elevators are optimised to thrive in the harsh environments often present in chemical plants with robust and durable designs.

Alimak also supports the construction of chemical plants with temporary vertical access solutions.

Auf dieser Seite

Typical chemical plant applications for industrial elevators include boilers, chimneys, crackers, LNG & LPG tanks and towers.

Shanxi Changqing Energy & Chemical Co

Shanxi Province of China

A robust external industrial elevator for an inclined chimney

Shaanxi Changqing Energy Chemical Co., Ltd. required a solution for practical vertical access to the chimney for daily monitoring of emissions. Alimak delivered an industrial elevator capable of ascending the chimney’s tapered incline for a robust and reliable vertical access solution.

Weiterlesen

Dyno Nobel Ammonium Nitrate Plant

QLD, Australia

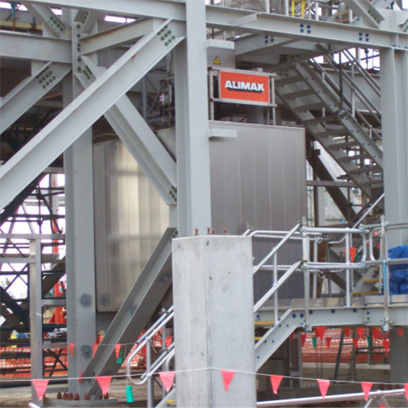

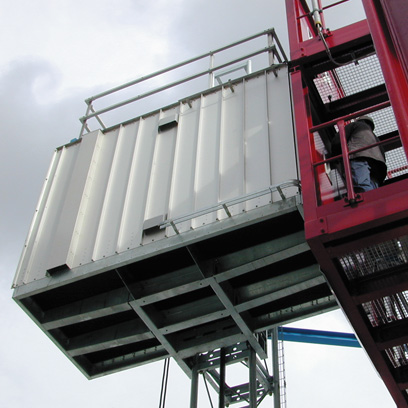

Alimak rack and pinion lift provides maintenance access to ammonium nitrate prill tower

An Alimak rack and pinion elevator was incorporated into the design of the ammonium nitrate prill tower at the Dyno Nobel Ammonium Nitrate Plant. With a lifting height of 70 metres, the SE 700 industrial elevator is utilised to create access for maintenance on the tower.

Weiterlesen

Bayer AG chemical plant

Dormagen, Germany

Alimak goods & passenger permanent elevator serves the chemical industry

An Alimak industrial elevator was installed at the Dormagen plant of Bayer AG, Germany, one of the world’s biggest chemical groups. The rack and pinion elevator is required to transport workers and bags of plastic granules to various levels of the plant up to 10 times per shift.

WeiterlesenDownload the Alimak Industrial Product Guide

Learn more about Alimak’s range of vertical access solutions.

View the Alimak range of vertical access products

Alimak industrial elevators deliver efficient and reliable vertical access for chemical plants.

Why choose an Alimak vertical access solution

Minimise climbing and manual handling

Tried and tested technology

Range of car sizes and capacities

Explosion proof available

Service and Support

Maintenance

A comprehensive range of maintenance services are available and carried out by trained Alimak Service technicians to ensure the ongoing optimal performance of equipment.

Find out moreConnectivity & asset management

Connectivity and asset management solutions report on the efficiency of industrial elevators and provide support to prolong the product lifecycle.

Find out moreApplication engineering

Alimak’s engineers develop customer-focused solutions for demanding installations. Tailored solutions include configuration drawings as well as strength, ground load and anchor force calculations.

Find out moreTraining

A range of safety, installation and operator training courses are available for Alimak’s range of products.

Find out moreFinancing Solutions

Alimak offers flexible finance solutions ranging from deferred payment terms, Export Finance to financial leases.

Find out moreBIM Modelling

Building Information Modelling is available for simulations, installations and the integration of industrial elevators at any point in a project.

Mehr erfahrenGet more information or a quotation

Need help with product selection for an upcoming project? Get in touch with our product experts for information on the range of vertical access solutions available and a quotation to meet the needs of your project.