Alimak service technicians identify and replace 70 m of corroded mast and base frame to extend the life of a 26-year-old maintenance lift. Given the close proximity to power lines and the confined space, a clever solution was required to complete the mast refurbishment.

Grain processing facilities

Founded in 1916, Graincorp operate seven bulk grain export elevators in Eastern Australia, boasting a combined grain storage capacity of 20 million tonnes. Processing wheat, barley, canola, chickpeas and sorghum, delivered by road and Graincorp’s extensive rail network, these facilities handle more than 5 million tonnes of grain annually.

Maintenance access

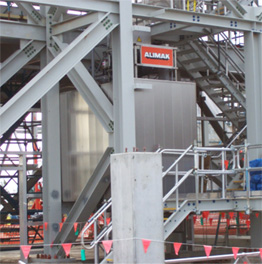

Installed in 1986, Graincorp’s Gladstone facility makes use of an Alimak rack and pinion lift to access the seven landings of their 70m grain stack. A critical piece of equipment on site, the Alimak lift allows maintenance staff to access higher levels of the stack for necessary servicing and maintenance. The lift also enables swift and safe access for emergency response if required.

Servicing identifies corrosion to the mast

Following an on-site service inspection, Alimak identified irreparable corrosive damage that had occurred to the base mast, base frame and a mast section located 25m up the grain stack. Both sections were damaged beyond repair and required the entire 70m mast and base frame to be dismantled and replaced.

Given the close proximity of power lines to the grain stack, Alimak was unable to angle a crane close enough to dismantle the lift mast. Without the use of a crane, mast sections could not be maneuvered over the power lines. A temporary disconnection of the lines would result in a shut down of Graincorp’s entire Queensland rail system.

A clever solution

In order to replace the damaged mast, Alimak engineered and installed a unique winch that would allow the mast to be dismantled and reassembled manually. Fixed to the Alimak lift car, the Alimak winch was able to hook each mast section individually and angle the section onto the lift car roof area. Operators were then able to use the lift itself to deliver each section to the ground.

In this way, each of the Gladstone grain stack’s 49 mast sections were manually dismantled, with the same process used in reverse to assemble the replacement mast. Alimak worked closely with Graincorp throughout the duration of the project, providing engineering technical, electrical and rigging support.

The Alimak rack and pinion lift’s replacement mast has been in operation at the Gladstone facility since May 2012, providing Graincorp operators with access to the 7 levels of the grain stack. Alimak’s manual winch approach may be used in future projects where site restrictions prevent crane access.

DETAILS

Location: Graincorp Grain Handling Facility, QLD, Australia

Installation year: 1986

Application: Grain handling facility, lift access

Lift type: Alimak Scando 10/19

No. of landings: 7

Capacity: 1000 kg

Car size: 1.9 m x 1.2 m

Speed: 0.65 m/sec

Lifting height: 70 m

GALLERY

An Alimak rack and pinion industrial elevator is pre-designed into Dyno Nobel’s Moranbah ammonium nitrate plant, providing maintenance access to the 70m prill tower. Alimak utilised a crane to lower the elevator into the existing tower shaft during installation.

A growing demand for mining explosives

The Dyno Nobel ammonium nitrate plant, located in Queensland’s coal-rich Bowen Basin, is part of Incitec Pivot’s $935 million Moranbah nitrate manufacturing complex. The fully-integrated back-to-gas complex includes ammonia, nitric acid and ammonium nitrate plants, producing the raw materials needed to service Australia’s growing demand for mining explosives. Construction of the complex began in 2006, and after several scheduling delays, was completed in early 2012.

Providing access to the penthouse

Included in the construction of the ammonium nitrate plant was the erection of a 70m prill tower to be used in the ammonium nitrate solidification process. Dyno Nobel specified the inclusion of an Alimak rack and pinion industrial elevator into the design of the prill tower, in order to provide operations and maintenance staff with access to the tower’s top ‘penthouse’.

Alimak worked closely with Dyno Nobel, providing engineering support for the design of the tie-in points and landings, pit design and electrical supply requirements.

Installation within a pre-existing elevator shaft

Installation of the industrial elevator proved challenging, with the elevator to be installed within a pre-existing shaft area of the prill tower. To accomplish this, elevator components were lowered from the 70m tower using cranes, while the Alimak installation team used a crane-hung ‘dog-box’ to access main tie-in points.

With a lifting height of 65m, providing access to the three landings of the prill tower, the Alimak industrial elevator is used for general maintenance on a daily basis and accommodates extra personnel and equipment during heavy-usage shutdown periods.

DETAILS

Location: Dyno Nobel Ammonium Nitrate Plant, Moranbah, Australia

Application: Prill tower, access elevator

Elevator type: Rack and pinion

Elevator model: ALIMAK SE 700

Capacity: 700 kg

Elevator car size: 1.04 m x 1.17 m x 2.17 m (W x L x H)

Speed: 1.0 m/s

Lifting height: 65 m

GALLERY

Crushing Services International specifies three Alimak SE 1200 kg industrial lifts for inclusion on the Christmas Creek Mine expansion. Installed in the mine’s iron ore processing facilities, these are the first permanent Alimak lifts in Australia installed on an iron ore crushing plant.

Iron ore mining expansion

Fortescue Metal’s Christmas Creek mining operations has undergone a two phase expansion program to increase the capacity of the mine’s iron ore operations. Located in the east Pilbara region of Western Australia, the Christmas Creek mine expansion included the construction of two ore processing facilities and a crushing hub; the first in Australia to be fitted with Alimak industrial men and materials lifts. Completed in December 2012, the expansion has increased production to more than 50 million tonnes of ore per annum.

Minimizing plant downtime

As the prime contractor for the expansion’s construction works, Crushing Services International specified the inclusion of the lifts in the ore processing facilities in order to maximize plant reliability. Minimizing production downtime at the processing facilities was a critical factor, as the iron ore requires crushing, screening and processing prior to sale and transport. Used for the transportation of materials, equipment and the operations and maintenance personnel on site daily, the three Alimak SE 1200kg industrial lifts improve efficiency of operations at a key stage of the mine’s processing circuit.

Phase one: taking advantage of limited space

Phase one of the expansion involved the construction of a 20mtpa ore processing plant, used to crush, screen, scrub and de-sand the wet table ore. The first Alimak industrial lift was installed in the de-sands building of the processing plant in March 2011, and required careful engineering to fit the lift system inside an existing portion of the building’s structure. In order to take full advantage of the limited space available, an Alimak FE mast was selected for its narrower depth and smaller dimensions, in place of the standard Alimak 650 mast.

Phase two: a second and third elevator are installed

Phase two of the expansion included the construction of a second ore processing plant and a remote crushing hub. The second Alimak 1200kg industrial lift was installed in the facility’s tertiary crusher in May 2012, while February 2013 saw the final Alimak lift installed in Plant 2’s de-sands building.

Improving safety and efficiency on-site

The Alimak SE 1200kg personnel and materials lift was selected for all three buildings due to its flexible size. With a car size of 1.3 m x 2.1 m, the Alimak SE 1200 is suited to carry palletized loads and improves safety and emergency procedures on site by accommodating the dimensions of an emergency stretcher.

Elevator details

Location: WA, Australia

Product Model: Alimak SE 1200

Lift Type: Rack and Pinion

Application: Iron ore processing facility, lift access

No. of Lifts: 3

Capacity: 1200 kg

Car Size: 1.3 m x 2.1 m

Speed: 0.6m /sec